Cord Winding & Placement Tools

Robot tools for automated cord winding of reinforced rubber products

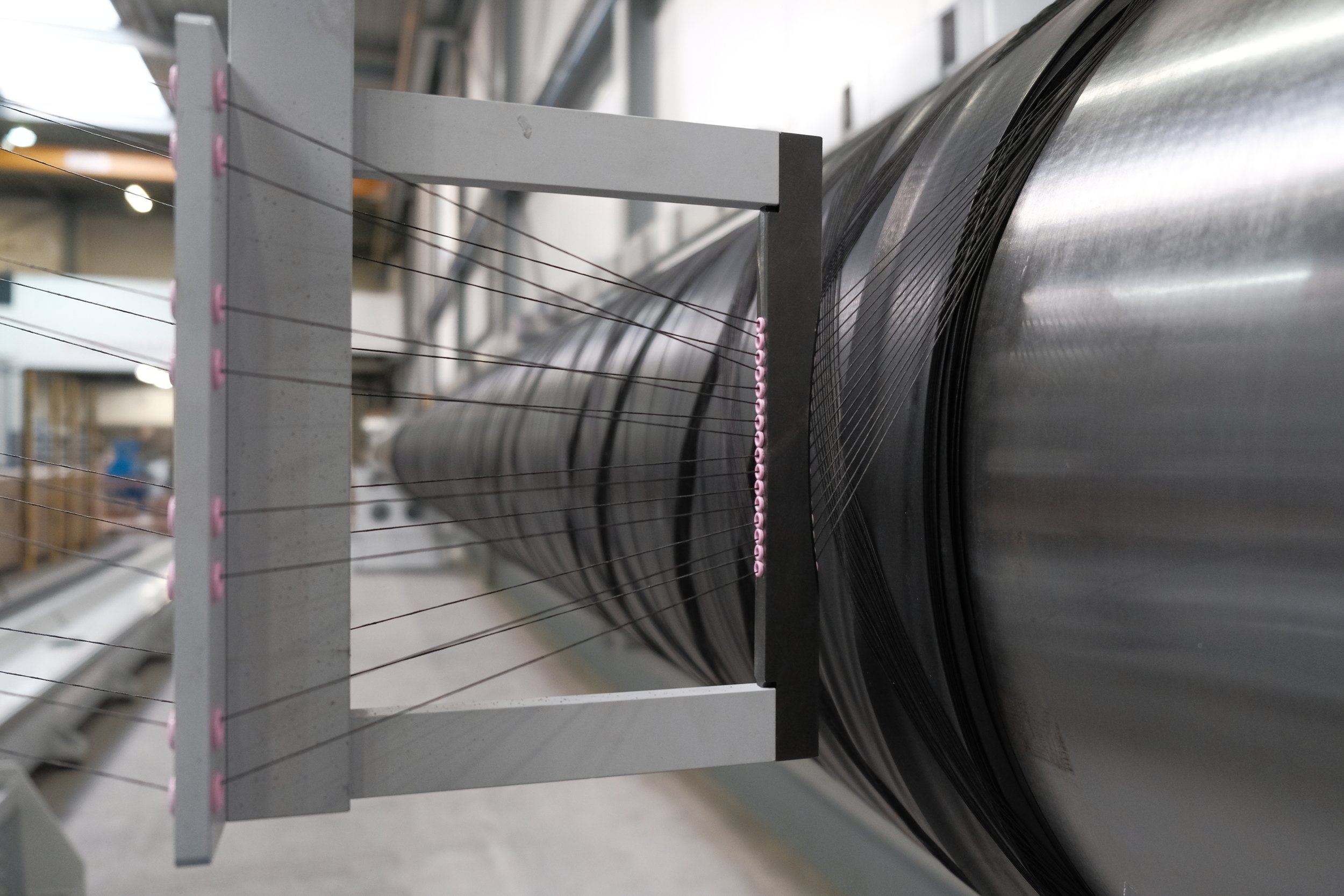

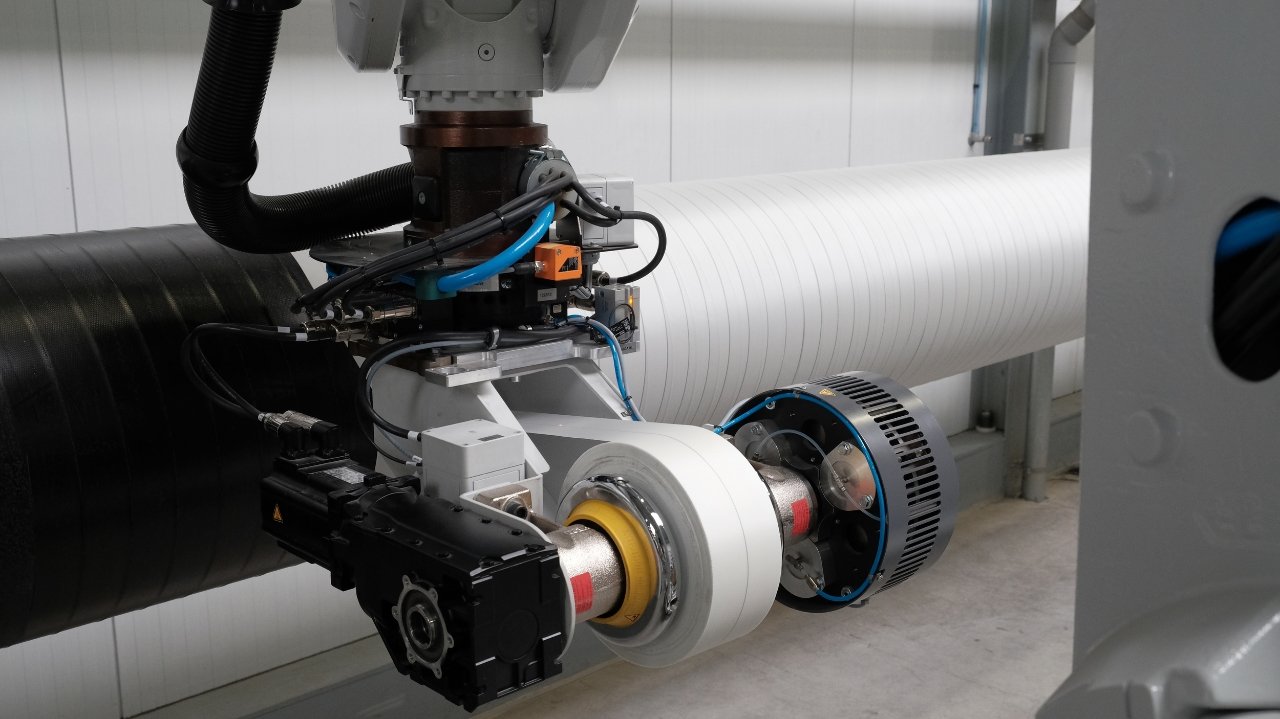

TANIQ has developed multiple special cord winding tools that are connected to the end of the robot arm. Using individual cords with an optimum structure instead of conventional sheet material brings significant advantages. The main function of the cord winding tool is to guide the cords from the tensioning equipment to the product. The design of the tool is determined by; the number of cords it has to guide, the type of cord construction and by the shape of the product that needs to be wound. To prevent friction and cord damage during winding, the rollers and eyelets used are made of special (coated) materials (e.g. ceramics). TANIQ has the expertise to design the optimal cord winding tools for each product.

Cord Winding

The Cord Winding Tools have been specially developed by TANIQ to place the cords accurately on the desired path. The link between the different components of TANIQ's robotic automation setup make this possible.

The design software uses parametric input to calculate the optimum cord reinforcement structure of the product. This structure is based on the desired product performance and the used materials (cord configuration and properties, rubber properties and tape specifications). The design software will generate a production file that coordinates the robot to manufacture this exact product. To generate the cord winding processes of the production file, the software uses the exact robotic configuration including e.g. the exact dimensions of the tool; the mandrel dimensions; and the axis of freedom of the robot arm. By doing so, the product is manufactured exactly (1:1) as designed.

Cord Winding Tools

Currently, there are two standard tool configurations: a medium size robotics tool for 4 cords and a XL large hose tool for 16 cords. The tools can be used to wind a large variety of cord types - as long as the cord thickness fits the outlet eyelets of the tools. TANIQ has extensive experience with different configurations. As a result, the tools can be customised to suit the specific cord specifications and application it is used for. Customiseble options:

Number of cords (requires customised tensioning equipment)

Cord eyelets to facilitate specific cord thickness

Tool shape and dimensions (for specific products)

Cord Tensioning Equipment

During the robotic winding process the tension in the cords should be constant to obtain a high and uniform product quality. TANIQ has developed special cord tensioning systems for the robotic setups.