Automation

At TANIQ, we believe automation starts with design. Instead of trying to force manual reinforcement methods into robotic production, we engineer new product design and reinforcement patterns that are created specifically for automated manufacturing. The design-driven approach results in products that are stronger, more consistent, and easier to produce at scale, even with low and medium volumes.

Smarter way to build reinforced rubber products

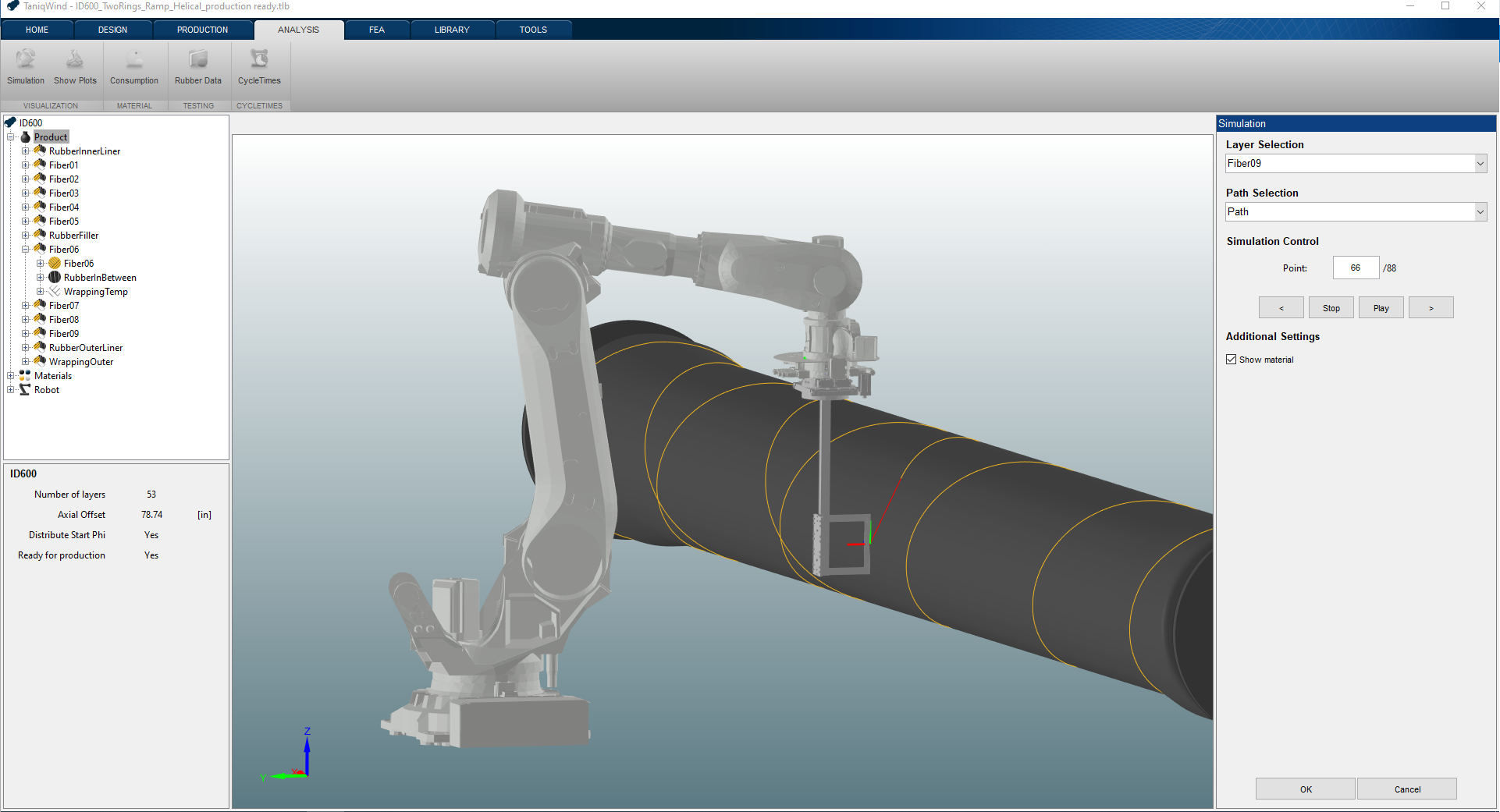

Design & Simulation

Our proprietary design environment enables engineers to:

Model and optimize reinforcement layers for hoses, bellows, pipe plugs, expansion joints, and other mandrel-built products.

Simulate winding patterns, fiber angles, and material use to achieve the best balance between strength, flexibility, and weight.

Validate with FEA (Finite Element Analysis) exports, so you know your product will perform before it’s built.

The software captures years of expertise in reinforced rubber design, turning complex know-how into an intuitive digital workflow.

Robotic Winding Systems

Our Scorpo robotic winding systems translate the optimized design into production with unmatched accuracy and repeatability.

Automated cord and tape placement ensures perfect layer build-up every time.

Configurable setups accommodate large mandrels (up to 20 m and 20 ton) and different product types.

Intuitive control and monitoring support efficient, safe operation with reduced dependency on manual labor.

Together, the software and robots create a seamless digital thread — from first concept to automated, validated production.