Our Services

From product idea to production and maintenance - powered by TANIQ’s expertise

Partnering with TANIQ, you’re not only getting an equipment or software, you get a trusted collaborator for your project, from designing the most optimal product for automation, to production and long-term maintenance. TANIQ is there to support you in every phase. As your collaborator

Product Development

The foundation behind optimising products: research on reinforced rubber cord structures.

Process Development

Product flanges/couplings, mandrel design, production tools, testing and material types.

Setting up Production

Research and development of (mathematical) models, software and simulation solutions.

Service & Maintenance

Development of robot components, robotic equipment, tensioners and tools.

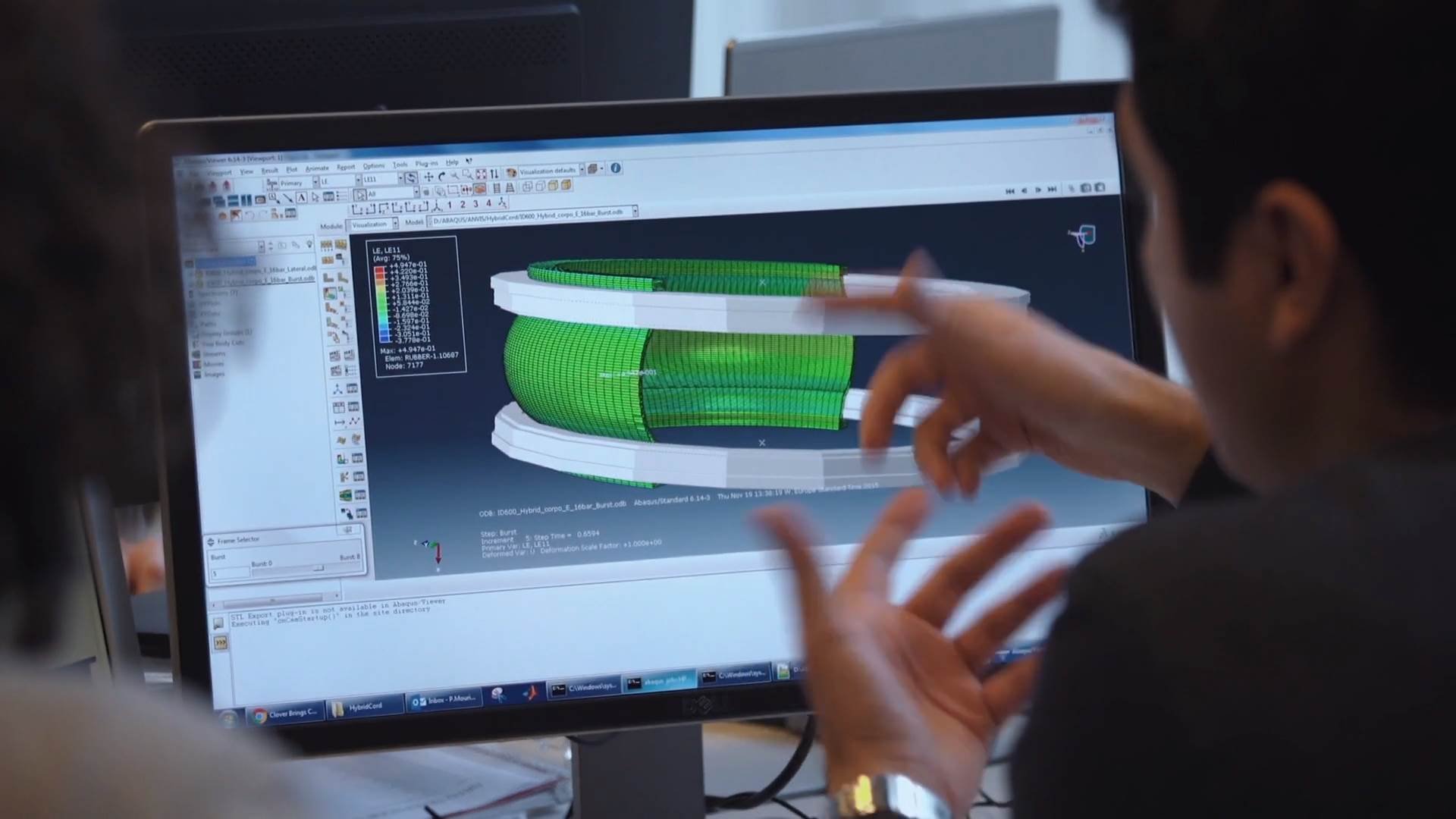

Product Development

We begin with concept and feasibility studies. Using our expertise in reinforced rubber and cord architectures, we help you design the optimal product not only for performance, but also for automation and scalability.

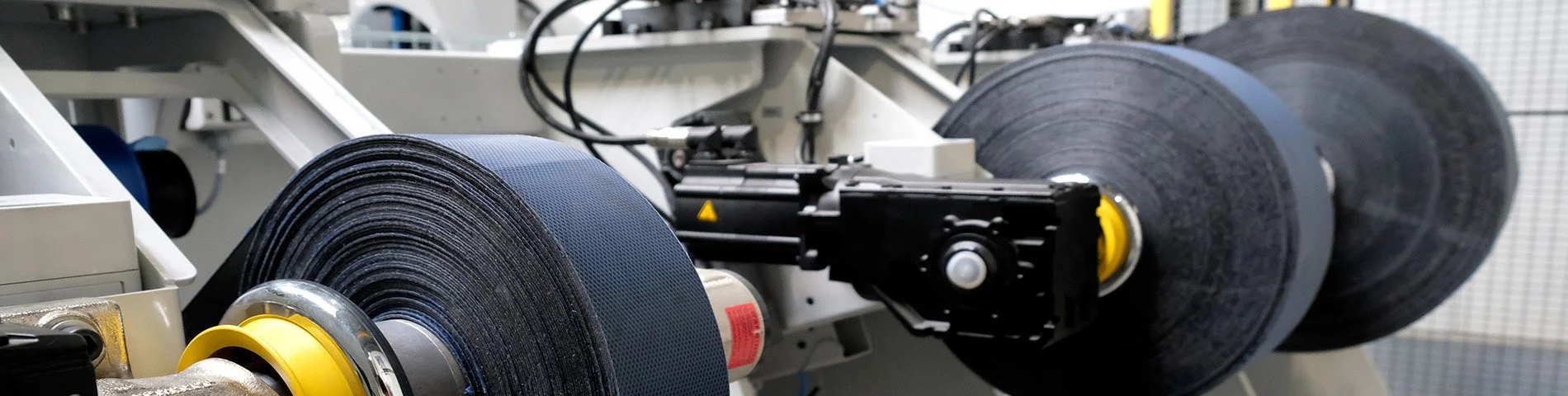

Process Development

Once the product design is defined, we develop the production process: mandrel design, tooling, couplings, flanges, material handling, and test methods.

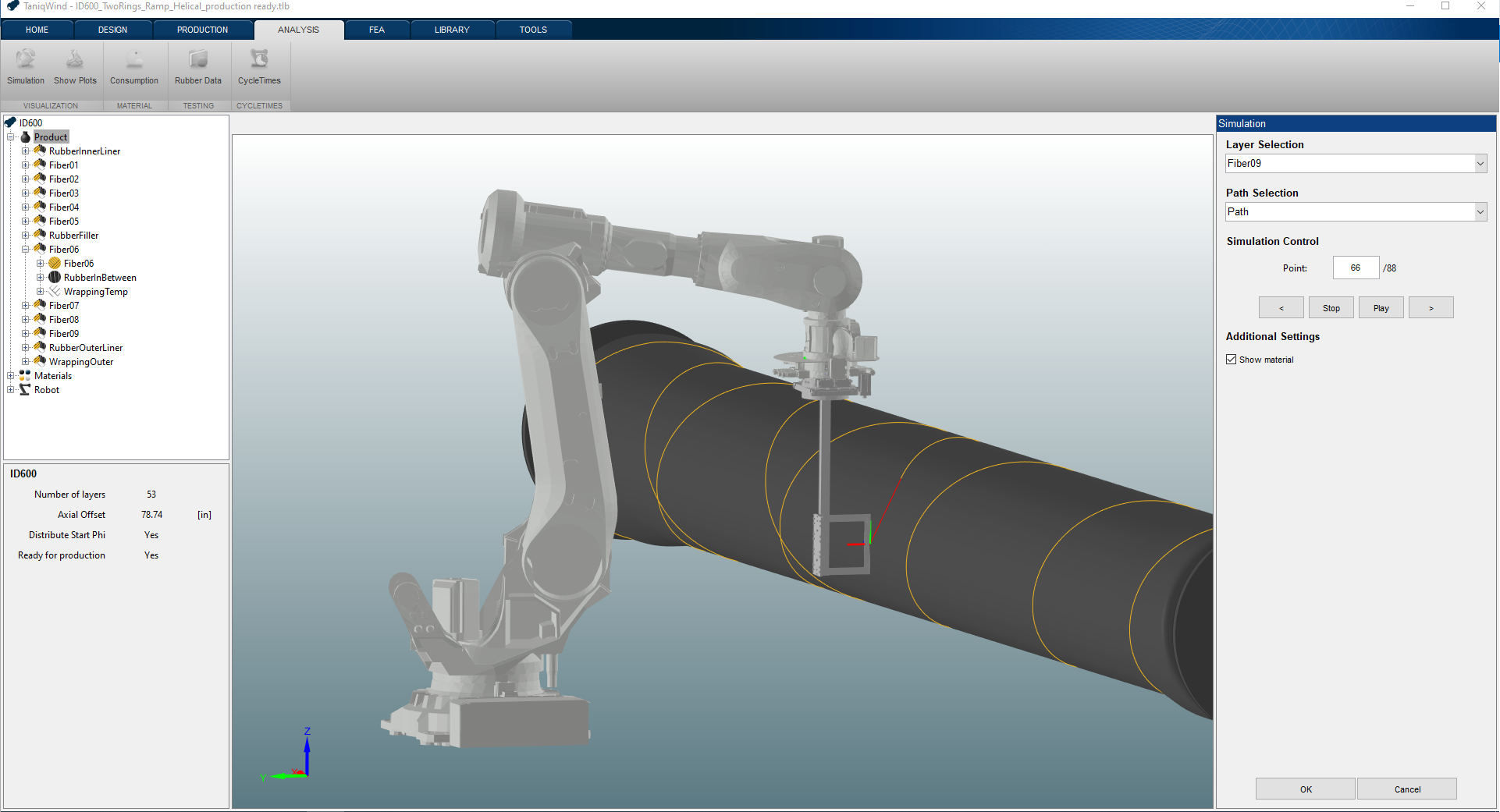

We simulate and refine the winding paths, build prototypes, and validate that the process is robust and repeatable.

Setting up production

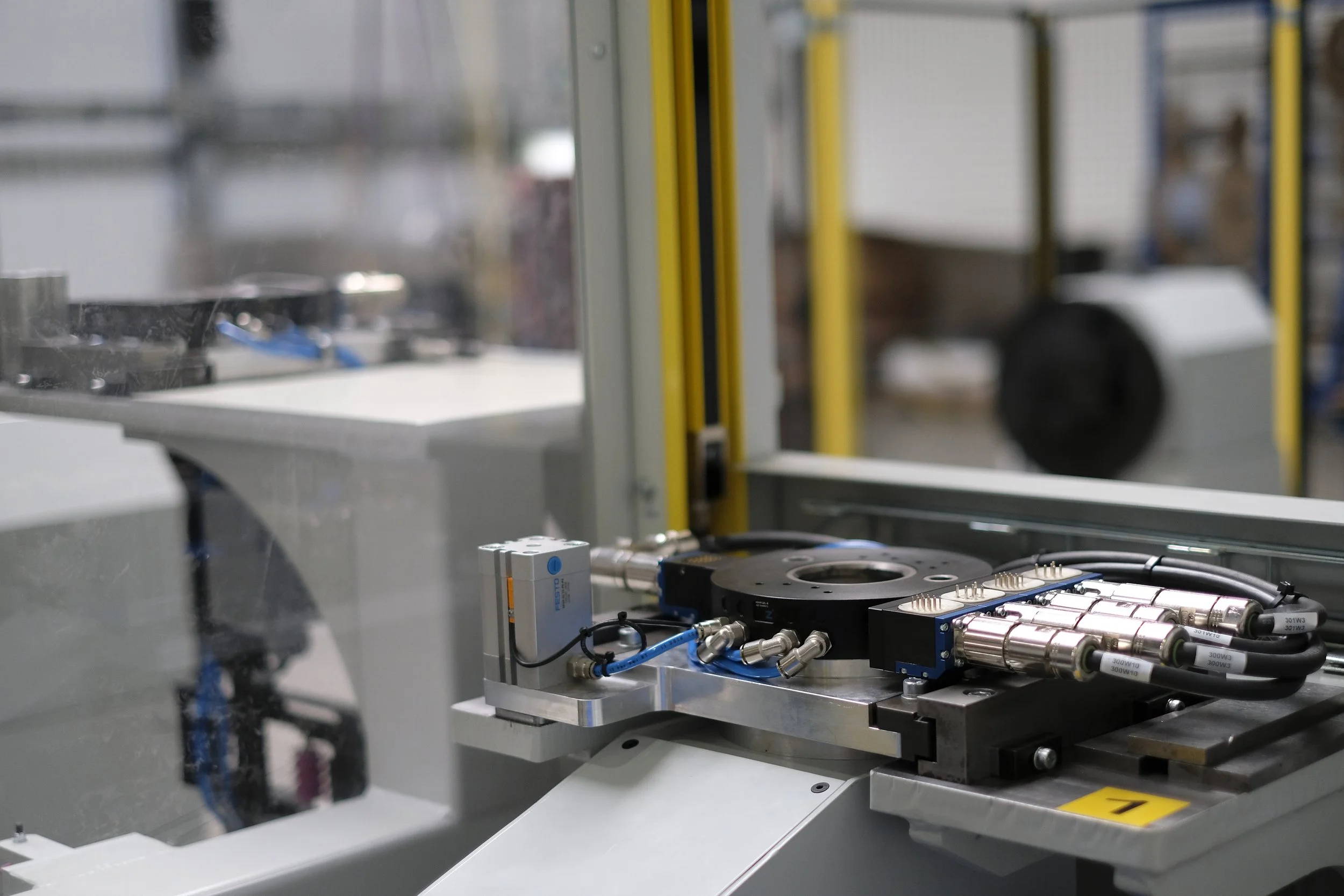

We assist in building out your factory floor: selecting, customizing, installing, and commissioning robotic winding equipment, control systems, and peripheral systems.

The design software, robot controllers, and tooling all integrate into your operations. As part of the handover, we train your operators and process staff. We ensure your line is ready for full production runs.

Service & Maintenance

As your production operates, TANIQ remains your technical partner: performing regular maintenance, rolling out software/hardware updates, troubleshooting, and offering remote support when needed.

We embed continuous R&D in our model, TANIQ dedicates roughly 10,000 hours per year to advance our tools, systems, and services, so your system can evolve with future upgrades.

Benefit from TANIQ's expertise to successfully develop your new products

TANIQ has developed new technology, which introduces possibilities for design optimization and process automation. We use our unique technology and expertise to assist manufacturers with optimizing existing products or creating new products, and automating their production processes. TANIQ has more than 15 years of experience in developing new products and automated production systems. Moreover, TANIQ is an experienced and dedicated partner to assist your organization in this process.

TANIQ has successfully worked together with SME’s and large multinationals to develop new products and set-up automated productions for lifting bags, pipe-plugs, expansion joints, large diameter hoses and other specialty applications. Using the design software and flexible robotic set-up enables to easily make new designs. Furthermore, TANIQ is available for assistance and provides regular updates and technological improvements, such that their Clients stay ahead of their competition.

TANIQ is an R&D company and is continuously working on developing new technology for optimization and automation of reinforced rubber products and composite products. To determine if a product design can be optimized and the production can be automated we typically start with a Feasibility study comprising product prototyping and business case calculations. In our work confidentiality is of key-importance and we always work under mutual non-disclosure agreement. If you are interested to determine the possibilities for your organization, we are looking forward to look together what TANIQ could do for you.