Cord Tensioning Equipment

Cord tensioning equipment for robotic winding

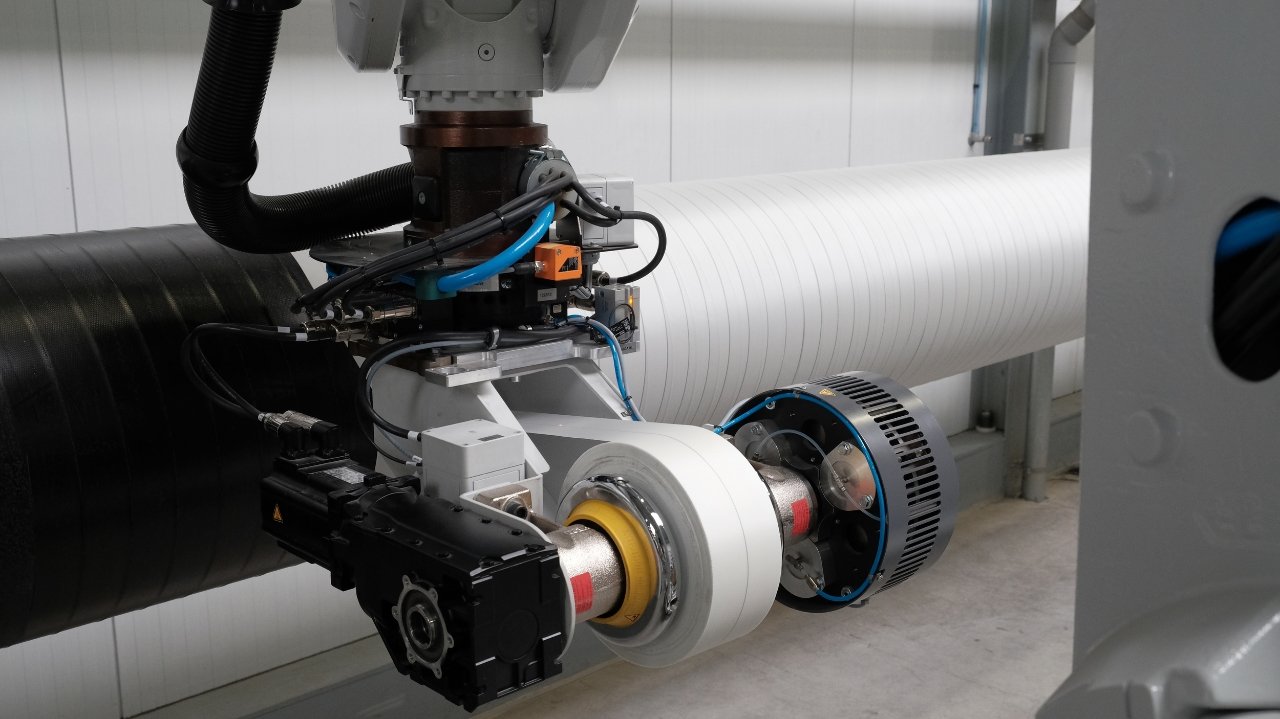

During the robotic winding process the tension in the cords should be constant to obtain a high and uniform product quality. Keeping the cord tension constant is challenging for production of complex shaped products, resulting in extreme robot movements and high accelerations and decelerations. TANIQ has developed special tensioning equipment that can be customized for specific applications and winding processes. Because of actively controlled tensioning arms, the tension is kept constant and ensures accurate placement by the winding tool even at high winding speeds, accelerations and decelerations. Thanks to in-house developement and its design, the system can be used with a wide variety of cord types - even sticky rubberized cords. In the design of the equipment rollers and special (ceramic) coatings are used to prevent friction on, or abrasion of, the cords during the winding process.

Selection and customization of cord tensioning equipment

TANIQ has developed multiple tensioning systems for specific purposes. The requirements are determined by the product and the fibre winding process. The winding of straight cylinder for example is possible with relatively simple tensioning equipment, while the winding of complex shaped products (e.g large elbow hose) will require a more complex system.

TANIQ has tested many different tensioning systems in their prototyping facility and can select the optimal system for each production process. TANIQ will modify the equipment to customize it to the robotic winding process and type of cords (e.g. dry/RFL/rubberised). The number of positions and bobbin size can be customised.

TANIQ's cord tensioning equipment

TANIQ has developed two standardised tensioning set-ups: one set-up for high acceleration and deceleration purposes and one less complex setup for less demanding winding processes.

The first setup has been specially developed for products such as expansion joints, pipe plugs, lift bags and convoluted hoses. The varying contours of the products and continuous winding process require the winding tool to accelerate and decelerate very quickly. To provide the cords under constant tension, the system is equipped with a regulating servo and tensioning arm for each bobbin. The setup is normally equipped with 4 positions.

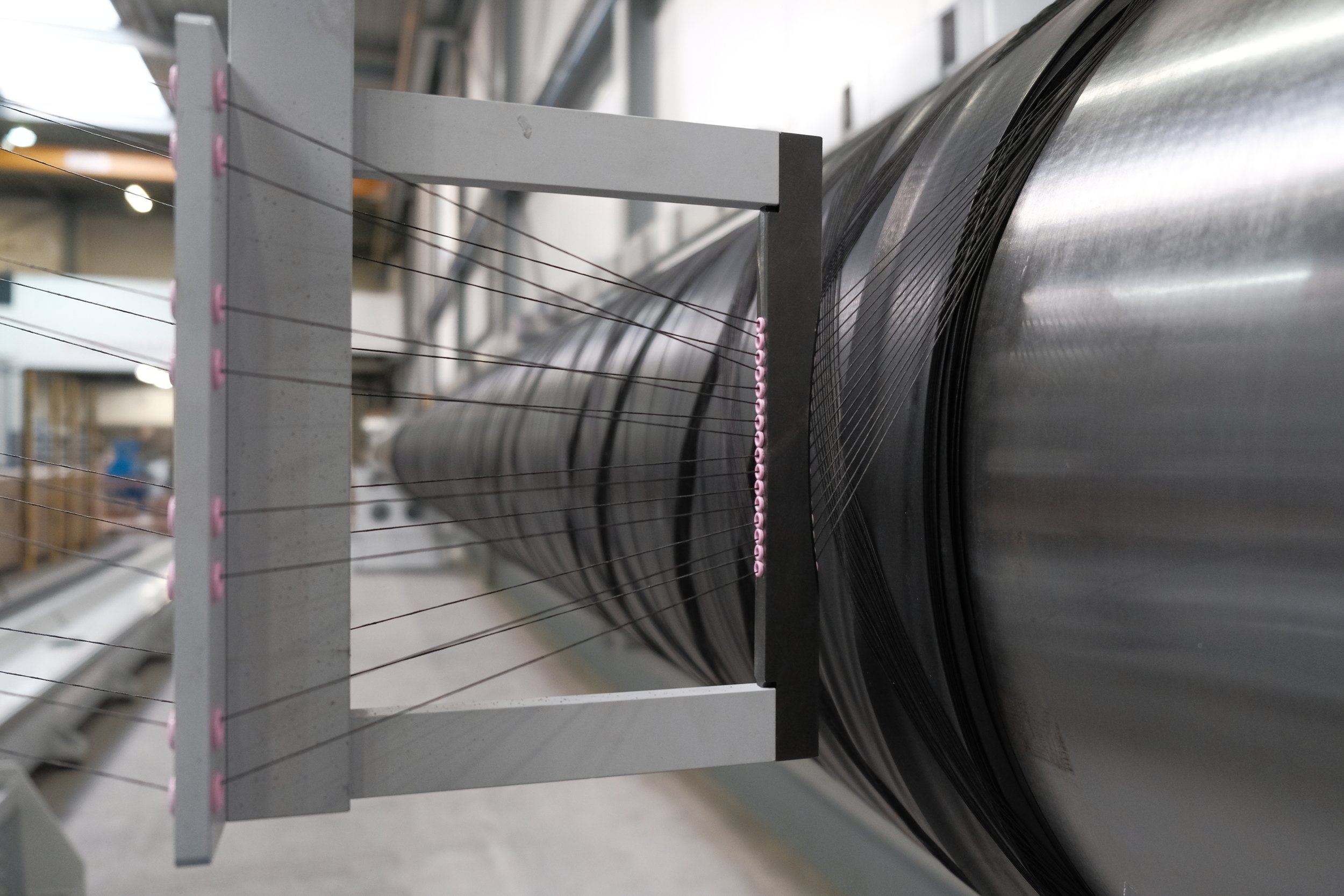

The second setup has been specially developed for large hoses and has 16 bobbin positions. Special servos control the tension of each cord. The whole tensioning setup moves simultaneously with the robot arm along the large hose mandrel on a track.

Both setups are equipped with automatic detection of empty bobbins and will warn the operator that refilling is required.