Process Development

Developing automation processes for rubber products

TANIQ has longtime experience and unique solutions for automated manufacturing of mandrel-built rubber products. TANIQ uses their expertise to assist manufacturers with developing automated production processes for their Applications. TANIQ uses an integral approach wherein a product design is optimized for performance as well as for automated manufacturing. This means that during the Product Development, the design is optimized taking into account the automated manufacturing thereof.

Most mandrel-built rubber products are manufactured by manual application of materials in sheet form (e.g. rubberized fabric sheets). This process has been used for over more than 40 years, and only possibility for incremental improvements are left. TANIQ offers an alternative which requires changing conventional design thinking, but introduces opportunities for significant improvements on the performance and costs side, paving the way for the next 40 years.

Automated process development

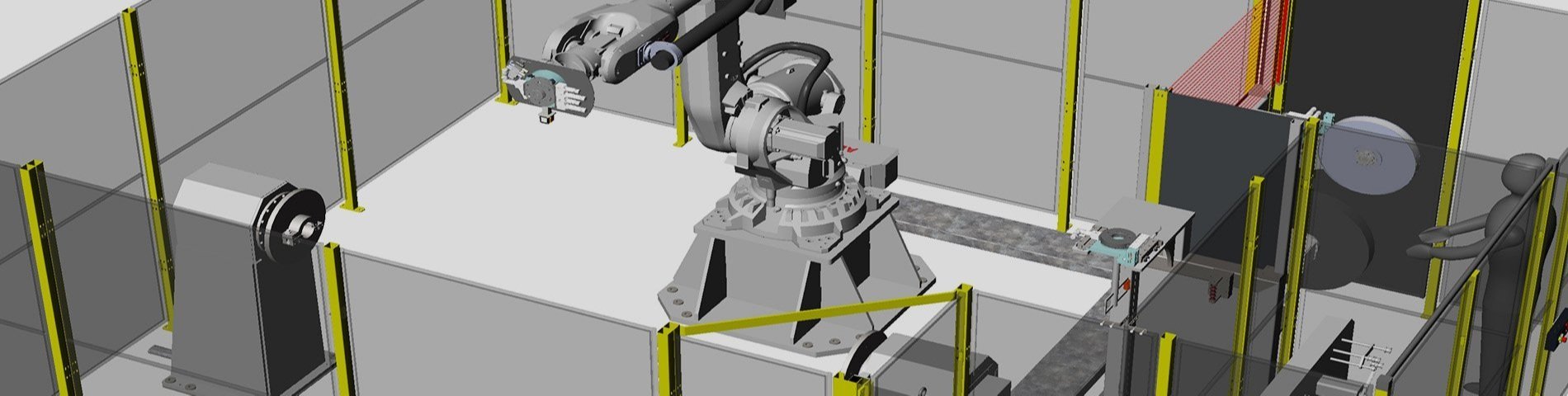

At the basis of the automated production process is a robotic system, which offers a flexible solution for winding of several materials, automatic cutting and attaching of materials enabling continuous production, pick-and place jobs, etc. TANIQ has already developed automated processes for a wide range of mandrel-built rubber products, resulting in unique experience in this niche. During a process development project TANIQ will work closely together with their Client, to develop the level of automation required.

TANIQ already has experience in developing the following processes:

Cord/fiber winding

Rubber winding

Tape winding

Label application

Cutting/Attaching

Mandrel picking/placing

Data logging

ERP integration

Flexible automation solutions

The automated process development is based on a combined solution of winding software and robotics. The winding software TaniqWind enables to make new designs and production programs of your products fast and efficiently. The robotic winding system enables to make a large variety of products on a single system. Together, these two parts enable to switch between different products fast and efficiently, providing a flexible solution for mandrel-built rubber products enabling ‘batch size one’.

TaniqWind Software

The TaniqWind Software plays an important role in the automation process. During development this software is used to develop your product designs, export these designs to FEA software for analysis, export the design to robotic process simulation software, and for generating winding programs for the robotic system. After the development phase, all know-how captured during the product and process development process will be embedded in a custom-made software dedicated for your product(s) and robotic winding system.

Robotic winding process

The first prototypes of your product will be developed on TANIQ’s robotic winding equipment. Besides physical winding, software can be used to simulate winding processes in a digital environment (digital twin). This allows to calculate production times or do reachability simulations for large/complex products in a digital environment, saving time and costs. For your final production the same prototyping processes could be used, or additional processes and tooling can be developed to further customize the production process to your needs.