Scorpo Custom Solutions

Automated production of reinforced rubber products

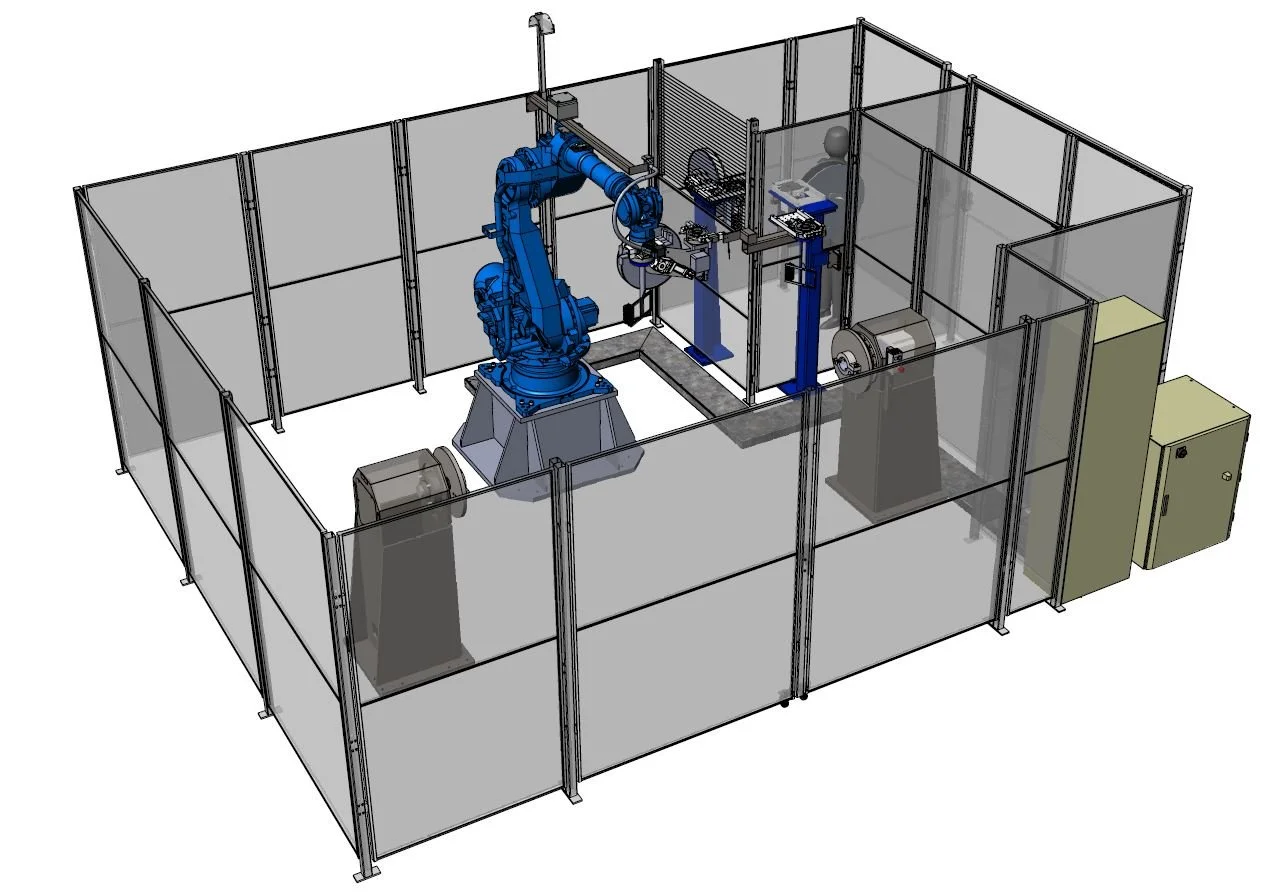

To automate the production of reinforced rubber products, TANIQ has developed the Scorpo Robotic system platform. Research and developments has resulted in a reliable automation solution for various applications. A large variation of products can be manufactured with a single robotic system that is capable of automated placement of rubber, reinforcement material and wrapping tape.

The overall design and operation of the robotic systems is identical from one robot cell to the other. However, because of the specific expertise and specialisms of different manufacturers in the industry, the systems can be customised per application and customer. Or completely custom systems can be developed. An overview is provided below.

The Scorpo systems can be adapted as is, or customised to requirements. To provide an overview of the system:

Custom automation solution platform

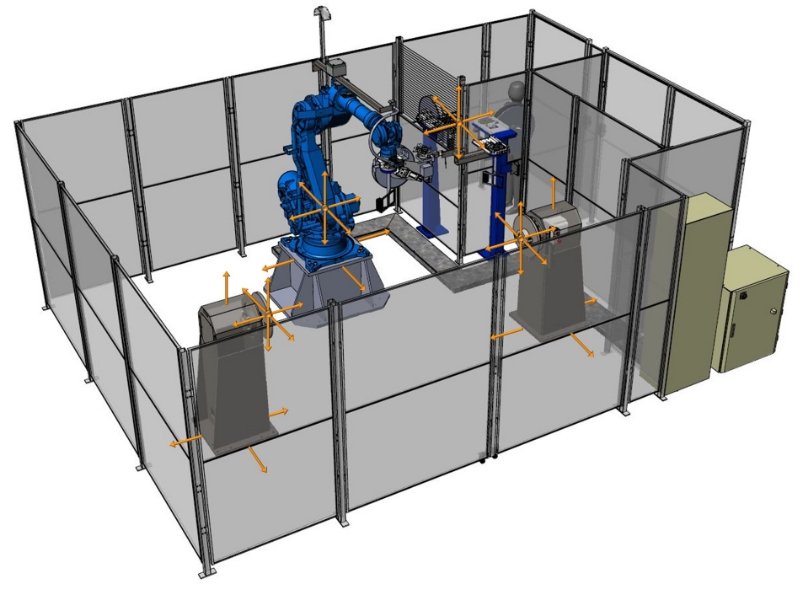

The standardised Scorpo Robotics can be used as a foundation for a customised setup. Examples of customisation:

Robotic arm (model and position)

Robotic arm pedestal or track

Special tensioner (number of positions)

Custom robotic tools

Custom tool station (number of tools/positions)

Mandrel rotator (axis-length, hight, position and power)

General layout of robot cell

Touchscreen interface

Safety system

Doors and fence

In addition, completely custom cells can be developed.

Customisation example gallery

Various robot arm models

Weight-class

Reach/Size

Tool-connector

Scorpo ONE

Scorpo GEMINI

Scorpo VIRGO

Scorpo TAURUS

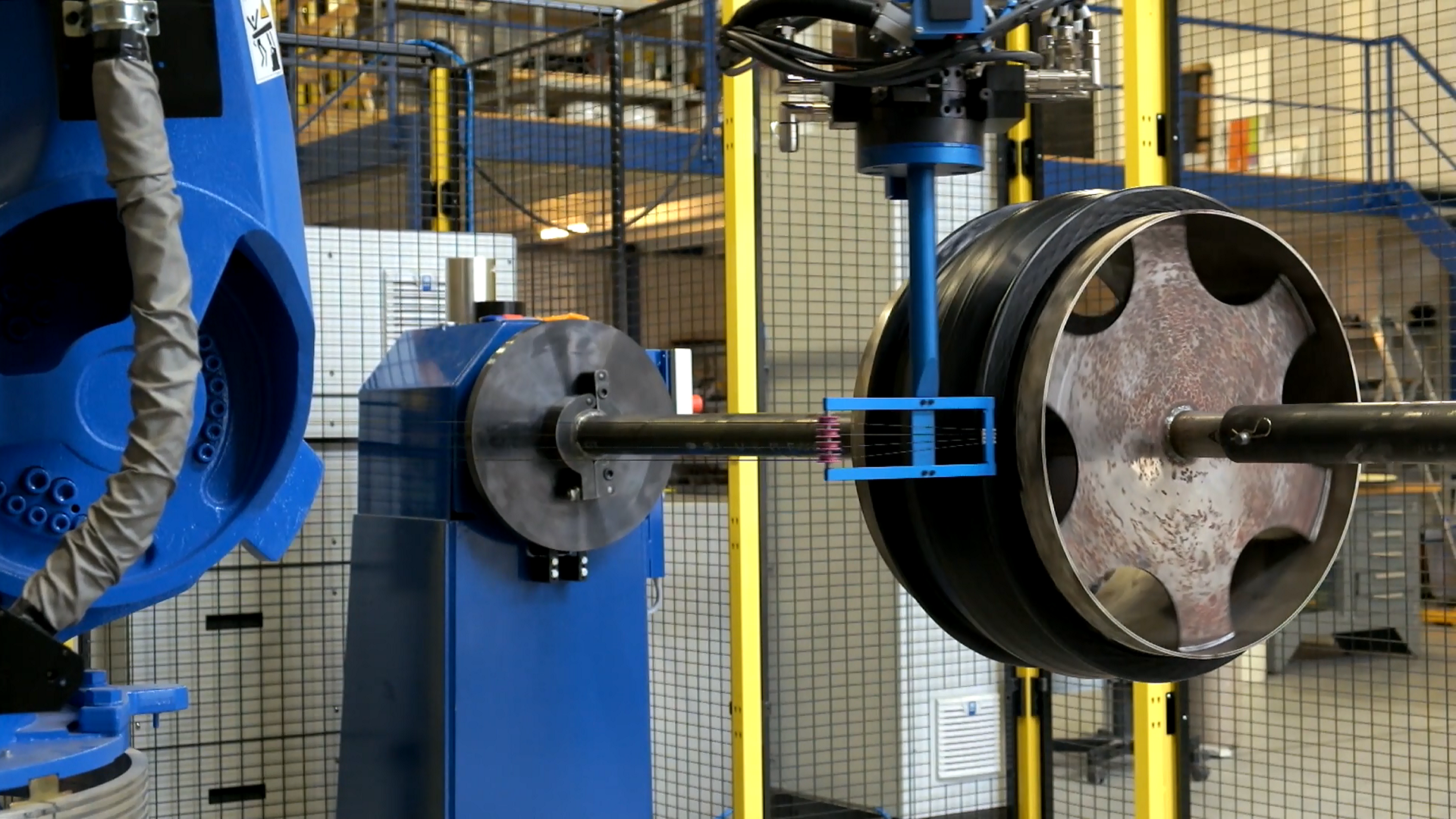

External Axis/Mandrel Rotators

Double Axis

Servo power

Axis positions

Pedestal or Track for robot arm

Track/Rails

Design/Size

Position