Product Development

Benefit from our experience to develop better products at lower costs

TANIQ has more than 15 years of experience in assisting Clients with product development for a large variety of reinforced rubber products. TANIQ has developed an integral approach wherein a product design is optimized for performance as well as for automated manufacturing. TANIQ has developed technology for optimizing reinforcement designs and the automated robotic winding thereof. By applying this technology TANIQ enables to replace traditional designs which typically require labor intensive manufacturing. Common gains obtained are improved performance, reduced material costs and (fully) automated production solutions.

Read more about our Product Development approach in the sections below:

Agile Product Development: an efficient approach to product development

Feasibility Study: Analyze the technical and financial feasibility or your product development

FEA Study: Digitally analyze and compare designs before actual prototyping and testing

Project Approach: Agile Product Development

Our experience is that objectives and specifications change during development based on forthcoming insights. Therefore, using agile development principles enables to adapt easily on new priorities and obtain the maximum possible result within a given budget and time. Agile product development means that the budget/hours are predetermined, and the scope and key results of the project are formulated prior to the project. However, the exact activities and direction is determined during the project based on progress, results, and new insights. During weekly meetings the results and key results are discussed and accordingly the requirements and focus are revisited and re-prioritized. In this way, our Clients have a continuous overview of the results and progress and can determine their priorities based on forthcoming insights. A typical product development project takes 3-6 months depending on your requirements.

Feasibility Study: Analyze the technical and financial feasibility or your product development

For development projects we propose a Feasibility Study wherein we work closely together to analyze the technical and/or financial feasibility of your project. At the end of a Feasibility Study, you will have the technical results (e.g. successfully tested prototypes) and/or financial results to determine if you want to continue with further investments in your project (e.g. investing in automation equipment). The following activities are typical examples of what can be done during the product development project:

Product design

Product performance analysis using FEA software

Prototyping (using our robotic equipment)

Prototype testing (e.g. burst pressure and life cycle tests)

Calculating production times and material costs

Develop automated process

Return-on-investment (ROI) calculations

Documentation of project results

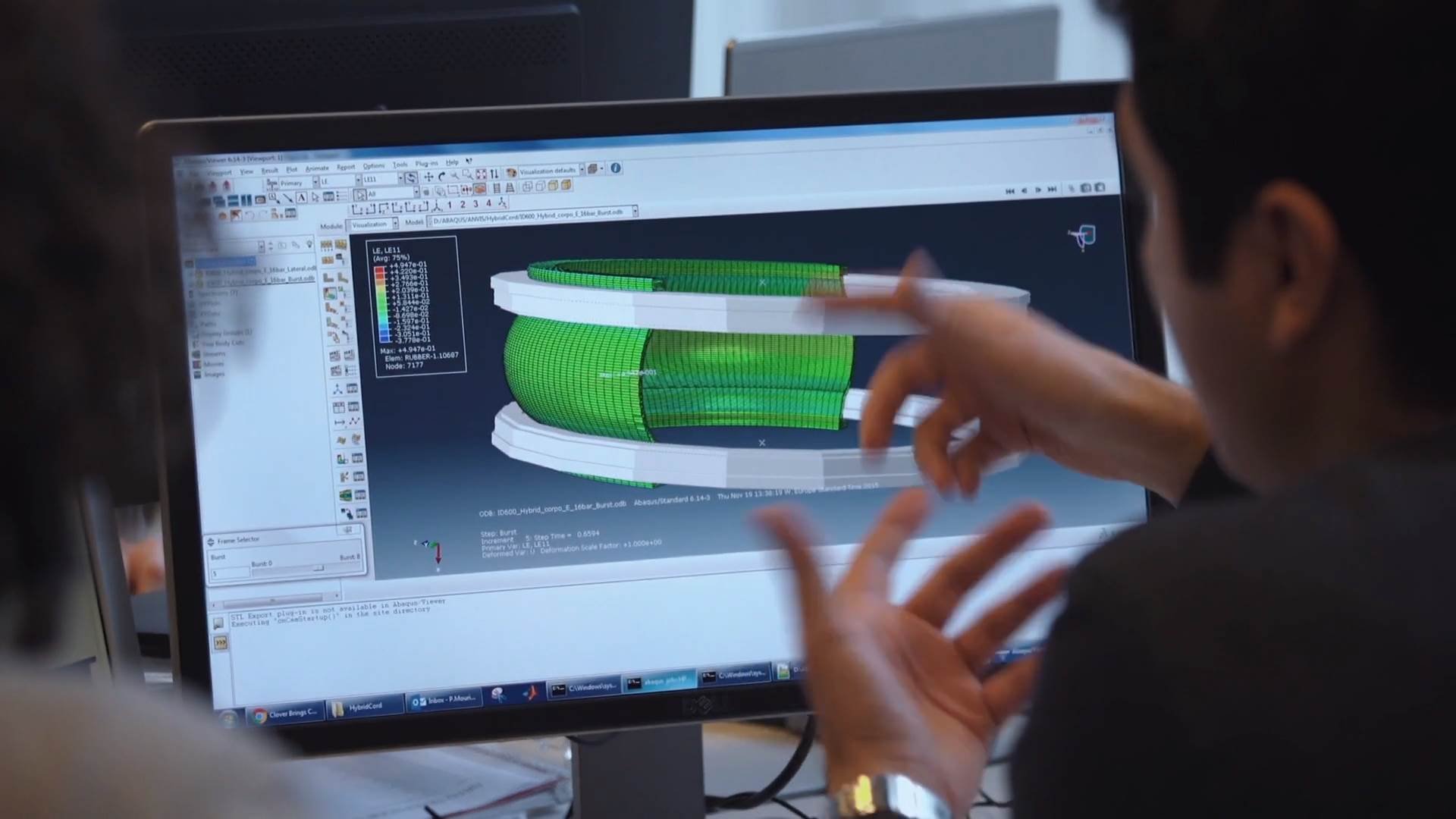

FEA Study: Digitally analyze and compare designs before actual prototyping and testing

Many manufacturers are interested in using FEA to analyze their reinforced rubber products, but don’t have the required expertise and software in-house. Therefore, TANIQ offers FEA Studies wherein we will develop your product model and analyze its behavior for different load cases for you. TANIQ can analyze the results and present them to you in an understandable manner. TANIQ's expertise of reinforced rubber products and FEA possibly also enables them to provide you with advice for design improvements. With an FEA Study you can analyze and optimize your product for various load cases, such as:

Burst pressure prediction (maximum fibre tensile strength)

Analysis of (local) stress concentrations

Stiffness responses/ load displacement curves

Failure mode prediction

Maximum movement capacity (axial compression/elongation, lateral deformation)

Surface sealing (e.g. leakage)

Buckling